Raw Materials

We make it a priority to select premium-quality raw materials for our production processes. Our hot-rolled steel strips are sourced from renowned steel production groups in China, known for their exceptional quality and consistency. These suppliers have a long-standing reputation for delivering high-grade steel, ensuring that the materials we use are reliable and meet stringent industry standards.

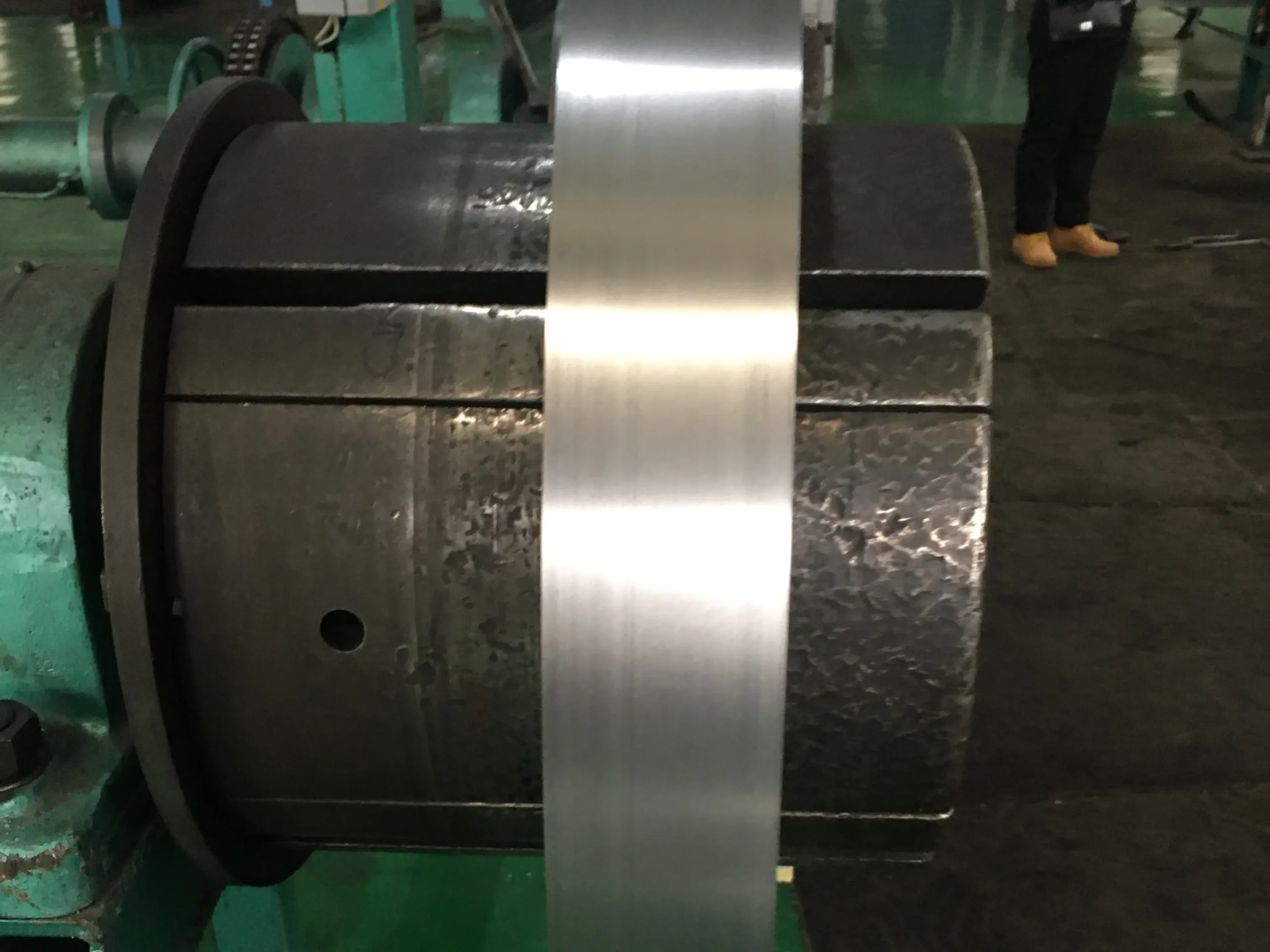

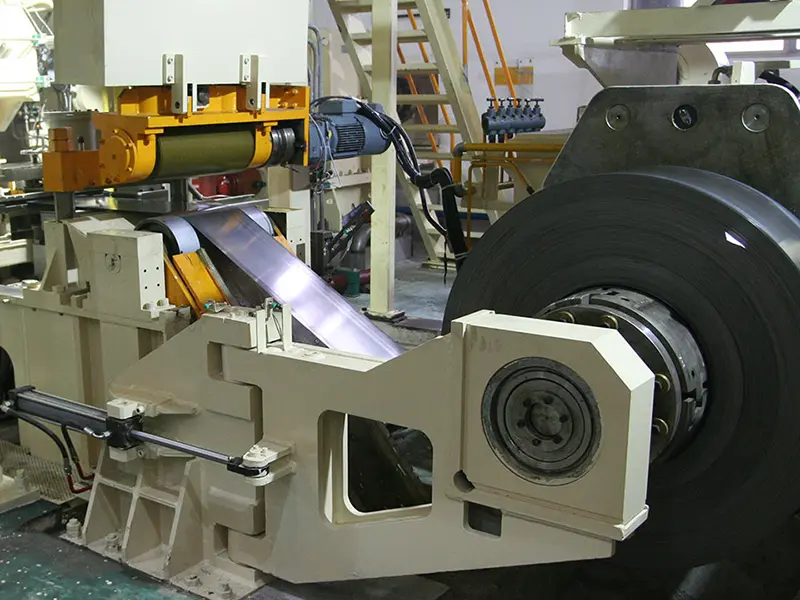

Steel Coil Slitting

We perform slitting operations on hot-rolled steel coils or wide cold-rolled coils. This process involves cutting the coils into narrower strips to meet specific width requirements, ensuring they are suitable for various applications. Our advanced slitting machinery allows for precise and efficient processing, maintaining the high quality and consistency of the steel strips.

Cold Rolling Process

We employ advanced production techniques and state-of-the-art equipment to manufacture high-end cold-rolled steel strip products. Our production processes are designed to enhance precision, efficiency, and quality, ensuring that our cold-rolled steel strips meet the stringent requirements of premium applications. By utilizing cutting-edge machinery and innovative methods, we can produce steel strips with exceptional surface finish, uniform thickness, and superior mechanical properties, catering to the needs of industries that demand the highest standards of performance and reliability.

Hot Treatment

We utilize various heat treatment methods, including oxygen-free bell-type annealing furnaces, lead bath quenching lines, oil quenching lines, and water quenching lines. These advanced techniques allow us to produce steel strips in a variety of colors, such as deep blue, light blue, yellow, and more. Our diverse heat treatment capabilities ensure that we can meet the specific aesthetic and performance requirements of our customers, providing them with high-quality, visually distinct steel products.

Steel Coil Straightening

After heat treatment, the dimensions of the steel strips may undergo slight changes. To ensure the final dimensional accuracy, our company implements an additional correction process. This step involves precise straightening and leveling techniques to guarantee that the steel strips meet the exact specifications required by our customers. By incorporating this extra measure, we ensure that our products maintain the highest standards of quality and performance.

Steel Coil Open Plate

We take the cold-rolled steel strips and flatten them into sheets to meet the specific requirements of some of our customers. This process involves uncoiling the steel strips and carefully leveling them to produce flat steel sheets. By offering this additional service, we can cater to customers who need flat steel plates for their projects, ensuring we meet a wider range of industrial and commercial needs. Our capability to provide both steel strips and flat sheets demonstrates our flexibility and commitment to satisfying diverse customer demands.

quality control

We implement stringent quality control measures to ensure the highest standards in our steel strips. This includes meticulous verification of dimensional accuracy and surface quality. Additionally, we conduct thorough performance tests to ensure that each steel strip meets the required specifications and standards. Only after passing these rigorous inspections do we approve the steel strips for shipment to our customers. This commitment to quality ensures that our products consistently meet or exceed customer expectations.

Packing and Shipping

We apply stringent anti-rust packaging to our cold-rolled steel strips. Given the extended transportation times and the possibility that customers may store our steel strips for an extended period, it is crucial to ensure that the products remain undamaged during transit and can be preserved for long-term use. Our specialized packaging methods are designed to protect the steel strips from corrosion and other forms of damage, guaranteeing that they arrive in pristine condition and retain their quality over time.