1.1274, 1095 compressor valve steel strip

1.1274, 1095 is a hardened and tempered carbon steel characterized by:

- High strength

- High fatigue strength under bending and impact stress

- Low level of non-metallic inclusions

- Good wear resistance

Compressor valve steel in 1.1274, 1095 has excellent surface finish, good dimensional tolerances and good flatness.

Standards

- ASTM: 1095

- Nr.: 1.1274

- SS: 1870

Chemical composition (nominal)

Chemical composition (nominal) %

| C | Si |

| 1.00 | 0.3 |

Applications

Valve production

Valves made from 1.1274, 1095 compressor valve steel should be produced with fatigue properties in mind, in order to make full use of the excellent material properties.

Valve types:

- Flapper valves

- Reed valves

- Check valves

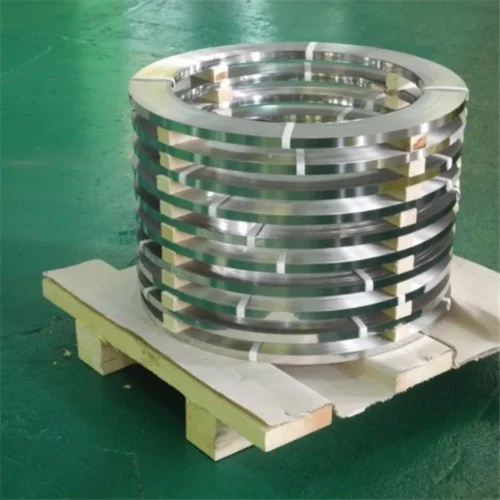

Forms of supply

Strip steel is supplied in labelled coils, or on labelled plastic spools, depending on weight and size. The label details the steel grade, heat, lot and coil number, and nominal size, allowing full material traceability. Material is protected against rust with oil.

Coils are wrapped in paper and packed in wooden cases. For overseas shipment, coils are also sealed in a plastic bag containing silica gel. Net and gross weights are marked on the case. Customized properties, dimensions and tolerances can be supplied on request.

Thickness

1.1274, 1095 comprevalve steel is supplied in standard thicknesses in accordance with the table.

| Thickness | Tolerance, ± | ||

| mm | in. | mm | in. |

| 0.152 | 0.006 | 0.005 | 0.00020 |

| 0.203 | 0.008 | 0.006 | 0.00024 |

| 0.254 | 0.010 | 0.007 | 0.00028 |

| 0.305 | 0.012 | 0.007 | 0.00028 |

| 0.381 | 0.015 | 0.008 | 0.00035 |

| 0.406 | 0.016 | 0.012 | 0.00047 |

| 0.457 | 0.018 | 0.012 | 0.00047 |

| 0.508 | 0.020 | 0.014 | 0.00055 |

| 0.559 | 0.022 | 0.020 | 0.00079 |

| 0.600 | 0.0236 | 0.020 | 0.00079 |

| 0.635 | 0.025 | 0.023 | 0.00091 |

| 0.762 | 0.030 | 0.023 | 0.00091 |

| 0.800 | 0.0315 | 0.027 | 0.00106 |

| 0.889 | 0.035 | 0.027 | 0.00106 |

| 1.000 | 0.0394 | 0.034 | 0.00134 |

Width

Strip in standard thicknesses is stocked in widths up to 350 mm (13.8 in.), ready for slitting to the required width.

Finishes

Edges

Edges are slit and deburred. Shaved edges can be supplied on request.

Flatness

Maximum out-of-flatness across and along the strip is 0.20% of the nominal strip width.

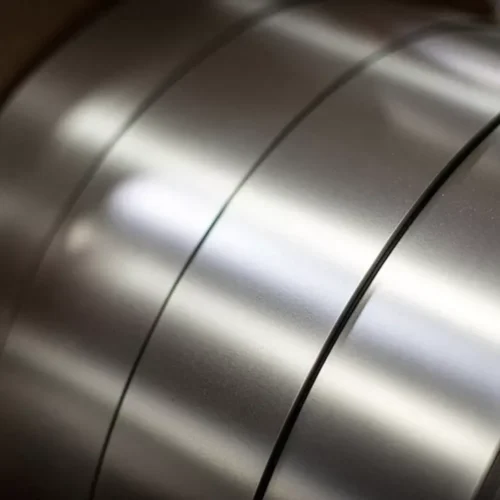

Surfaces

Material is delivered bright, fine polished.

Surface roughness

Maximum surface roughness values, cut-off 0.25 mm (.0098 inch), are shown in the table.

| Thickness | Ra | Rmax | |||

| mm | in. | µm | µin. | µm | µin. |

| <0.508 | <0.020 | 0.13 | 5.2 | 1.5 | 60 |

| >0.508 | >0.020 | 0.25 | 10.0 | 2.5 | 100 |

Surface defects

A small number of surface defects, such as pits and roll marks, with a depth or height of 2 µm (80 µin.) maximum is allowed for thicknesses up to 0.508 mm (0.020 in.) and 3 µm (120 µin.) maximum for thicker material. The maximum scratch depth allowed is as follows:

| Thickness | Max. allowed depth | ||

| mm | in. | µm | µin. |

| <0.203 | <0.008 | 0.5 | 20 |

| >0.203-<0.508 | >0.008-<0.020 | 0.8 | 32 |

| >0.508 | >0.020 | 1.0 | 40 |

Straightness

Out-of-straightness is defined as the maximum deviation from a straight-edge of a specified length. The following values apply:

| Strip width | Max. allowed deviation | ||

| mm | in. | mm/m | in./3 feet |

| >8-<20 | >0.315-<0.787 | 2.0 | 0.072 |

| >20-<50 | >0.787-<1.969 | 1.5 | 0.054 |

| >50-<125 | >1.969-<4.921 | 1.25 | 0.045 |

| >125 | >4.921 | 1.0 | 0.036 |

Mechanical properties

At 20ºC (68ºF)

| Thickness | Tensile strength | ||

| mm | in. | MPa | ksi |

| <0.125 | <0.005 | 2100 | 305 |

| 0.125-<0.175 | 0.005-<0.007 | 2050 | 297 |

| 0.175-<0.225 | 0.007-<0.009 | 2000 | 290 |

| 0.225-<0.275 | 0.009-<0.011 | 1950 | 283 |

| 0.275-<0.375 | 0.011-<0.015 | 1900 | 276 |

| 0.375-<0.425 | 0.015-<0.017 | 1850 | 268 |

| 0.425-<0.475 | 0.017-<0.019 | 1800 | 261 |

| 0.475-<0.625 | 0.019-<0.025 | 1750 | 254 |

| 0.625-<0.825 | 0.025-<0.033 | 1700 | 247 |

| 0.825-<1.000 | 0.033-<0.039 | 1650 | 239 |

The proof strength (Rp0.2) is approximately 90% of the tensile strength (Rm). The manufacturing tolerance for tensile strength is ±80 MPa (±11.6 ksi.)

Fatigue strength

1.1274, 1095 compressor valve steel has been used in the compressor industry for many years. The steel is tailored for applications requiring high fatigue strength. The fatigue strength depends on the surface and edge treatment of the material. The values presented are from none tumbled material with a smooth edge.

Physical properties

Density, 7.8 g/cm3, 0.28 lb/in3

Thermal conductivity

| At 20°C, W/(m °C) | 49 |

| At 68°F, Btu/(ft h °F) | 28 |

Specific heat capacity

| Mean value for 50-100°C, J/(kg °C) | 460 |

| Mean value for 120-210°F, Btu/(lb °F) | 0.11 |

Thermal expansion, mean values in temperature ranges (x 10-6)

| Temperature | Temperature | ||

| °C | Per °C | °F | Per °F |

| 30-100 | 10.5 | 86-200 | 5.5 |

| 30-200 | 11.5 | 86-400 | 6.5 |

| 30-300 | 12.5 | 86-600 | 7.0 |

Modulus of elasticity, static properties at 20°C (68°F)

| MPa | 210000 |

| ksi | 30500 |