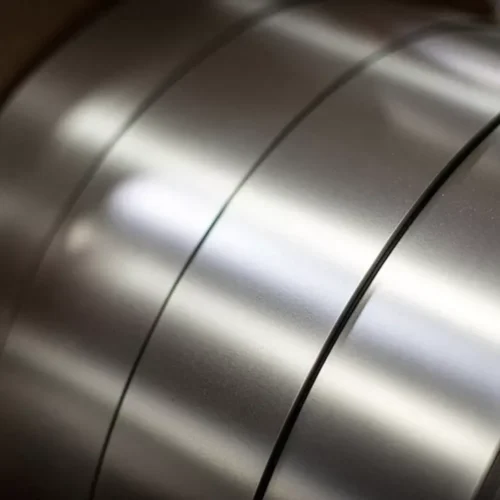

1095, 1.1274 for shock absorber shims steel strip

1095, 1.1274 is a hardened and tempered carbon steel used for shock absorber shims. 1095, 1.1274 shock absorber steel is characterized by:

- High strength and wear resistance

- High fatigue strength under bending and impact stress

- Excellent surface finish

- Low level of non-metallic inclusions

- Good dimensional tolerances

- Good flatness

Standards

- ASTM: 1095

- EN Number: 1.1274

Chemical composition (nominal)

Chemical composition (nominal) %

| C | Si | Mn | P | S | Cr |

| 1.0 | 0.3 | 0.4 | ≤0.020 | ≤0.010 | 0.2 |

Fabrication

Parts made from 1095, 1.1274 shock absorber steel should be produced with fatigue properties in mind, in order to make full use of the material’s properties.

Blanking

It is recommended that blanking is carried out in a straight-sided press, using blanking tools with sharp edges. Worn or damaged tools can cause edge defects. A punch to die clearance of 2-6% of the strip thickness is recommended. High-speed steel (AISI M2) and cemented carbide are used most often for the manufacture of punches and dies. In the majority of cases, we recommend M2. Alleima Hard Materials supplies suitable cemented carbide grades. For the correct choice of grade, we recommend reference to a specialist manufacturer of quality tooling.

Stress relieving

Stress relieving can be carried out between blanking and tumbling operations, in order to remove blanking stresses. A maximum temperature of 250°C (480°F) for 30-60 minutes is recommended.

Tumbling

A good tumbling operation is necessary, to give the appropriate edge roundness. Tumbling also increases the residual compressive surface stresses, which gives a further improvement to the fatigue properties.

Forms of supply

Strip steel is supplied in labelled coils. The label details the steel grade, heat, lot and coil number, and nominal size, allowing full material traceability. Material is protected against rust with oil. Coils are packed in wooden cases. For overseas shipment, coils are wrapped in paper and sealed in a plastic bag containing silica gel. Net and gross weights are marked on the case. Customized properties, dimensions and tolerances can be supplied on request.

Dimension

Thickness

1095, 1.1274 is supplied in standard thicknesses in accordance with the table below.

| Thickness | Tolerance, ± | ||

| mm | in. | mm | in. |

| 0.102 | 0.004 | 0.004 | 0.00016 |

| 0.114 | 0.0045 | 0.004 | 0.00016 |

| 0.152 | 0.006 | 0.005 | 0.00020 |

| 0.203 | 0.008 | 0.006 | 0.00024 |

| 0.254 | 0.010 | 0.007 | 0.00028 |

| 0.305 | 0.012 | 0.007 | 0.00028 |

| 0.381 | 0.015 | 0.008 | 0.00031 |

| 0.406 | 0.016 | 0.009 | 0.00035 |

| 0.457 | 0.018 | 0.009 | 0.00035 |

| 0.508 | 0.020 | 0.010 | 0.00039 |

| 0.559 | 0.022 | 0.010 | 0.00039 |

| 0.600 | 0.0236 | 0.010 | 0.00039 |

Material with closer tolerances can be supplied on request.

Width

Strip in standard thicknesses is stocked in widths up to 340 mm (13.39 in.), ready for slitting to the required width.

Finishes

Edges

Edges are slit and deburred. Shaved edges can be supplied on request.

Flatness

Maximum out-of-flatness across and along the strip is 0.30% of the nominal strip width.

Surfaces

Material is delivered bright, fine polished.

Surface roughness

Maximum surface roughness values, cut-off 0.25 (0.0098 in.), are shown in the table below.

| Thickness | Ra | Rmax | |||

| mm | in. | µm | µin. | µm | µin. |

| <0.508 | <0.020 | 0.13 | 3.9 | 1.5 | 60 |

| >0.508 | >0.020 | 0.25 | 10.0 | 2.5 | 100 |

Surface defects

A small number of surface defects, such as pits and roll marks, with a depth or height of up to 5 µm (200 µin.) maximum is allowed. The maximum scratch depth allowed is 2.0 µm (80 µ”).

Straightness

Out-of-straightness is defined as the maximum deviation from a straight-edge of specified length. The following values apply:

| Strip width | Maximum allowed deviation | ||

| mm | in. | mm/m | in./3 feet |

| >8-<20 | >0.315-<0.787 | 2.0 | 0.072 |

| >20-<50 | >0.787-<1.969 | 1.5 | 0.054 |

| >50-<125 | >1.969-<4.921 | 1.25 | 0.045 |

| >125 | >4.921 | 1.0 | 0.036 |

Strip can be supplied with closer straightness values on request.

Mechanical properties

Tensile strength, nominal values at 20 °C (68°F)

| Thickness | Tensile strength | ||

| mm | in. | MPa | ksi |

| <0.125 | <0.005 | 2100 | 305 |

| 0.125-<0.175 | 0.005-<0.007 | 2050 | 297 |

| 0.175-<0.225 | 0.007-<0.009 | 2000 | 290 |

| 0.225-<0.275 | 0.009-<0.011 | 1950 | 283 |

| 0.275-<0.375 | 0.011-<0.015 | 1900 | 276 |

| 0.375-<0.425 | 0.015-<0.017 | 1850 | 268 |

| 0.425-<0.475 | 0.017-<0.019 | 1800 | 261 |

| 0.475-<0.600 | 0.019-<0.0236 | 1750 | 254 |

The yield strength, Rp0.2, is approximately 90% of the tensile strength, Rm. The manufacturing tolerance for tensile strength is ±80 MPa (±11.6 ksi).

Fatigue strength

1095, 1.1274 shock absorber steel has high fatigue strength and is tailored to meet the demands of the shock absorber industry. It has proved, over a long period of time, to be a reliable material for shock absorbers.

Physical properties

Density

7.8 g/cm3, 0.28 lb/in3

Thermal conductivity

At 20°C, W/(m °C) 49

68°F, Btu/(ft h °F) 28

Specific heat capacity

Mean value for 50-100°C, J/(kg °C) 460

120-210°F, Btu/(lb °F) 0.11

Thermal expansion 1)

| Temperature | Temperature | ||

| °C | Per °C | °F | Per °F |

| 30-100 | 10.5 | 86-200 | 5.5 |

| 30-200 | 11.5 | 86-400 | 6.5 |

| 30-300 | 12.5 | 86-600 | 7.0 |

1) Mean values (x10-6)

Modulus of elasticity, at 20°C (68°F)

210 000 MPa, 30 500 ksi