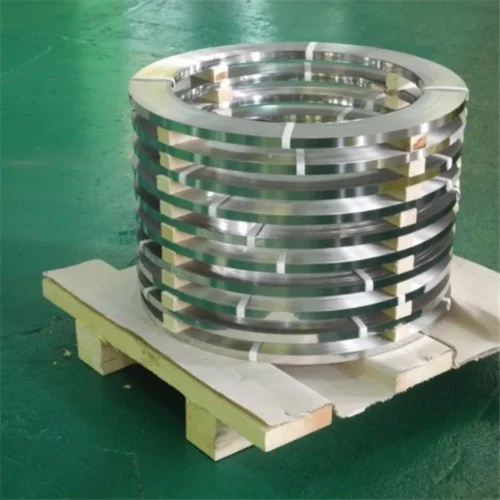

2507, S32750, 1.4410 spring stainless steel strip

2507, S32750, 1.4410 is a super-duplex (austenitic-ferritic) stainless steel for service in highly corrosive conditions. The grade is characterized by:

- Excellent resistance to stress corrosion cracking (SCC) in chloride-bearing environments

- Excellent resistance to pitting and crevice corrosion

- High resistance to general corrosion

- Very high mechanical strength

- Physical properties that offer design advantages

- High resistance to erosion corrosion and corrosion fatigue

- Good weldability

Standards

- UNS: S32750

- EN Number: 1.4410

- EN Name: X 2 CrNiMoN 25-7-4

Chemical composition (nominal)

Chemical composition (nominal) %

| C | Si | Mn | P | S | Cr | Ni | Mo |

| ≤0.030 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.015 | 25 | 7 | 4 |

Others: N=0.3

Applications

2507, S32750, 1.4410 strip can be used in general strip applications where a good corrosion resistance is required. It is especially suitable for

- Seawater applications

- Chloride-containing bleaching environments in the pulp and paper industry

- Chemical industry

In the cold-rolled condition 2507, S32750, 1.4410 is a very good spring material for corrosive environments.

In the annealed condition the combination of high yield strength and good corrosion resistance is inviting to a new design approach for a variety of applications. Especially allowing for non-corrosion protected light weight constructions with a low life cycle cost.

Corrosion resistance

General corrosion

2507, S32750, 1.4410 is highly resistant to corrosion by organic acids, e.g. formic and acetic acid. Also in chloride contaminated acid the grade remains resistant.

2507, S32750, 1.4410 in the annealed, cold-rolled as well as cold-rolled and aged condition has passed salt spray tests during 500 h according to ISO 9227:2006 without any attack.

Pitting corrosion

The pitting corrosion resistance was assessed electrochemically by the method ASTM G150. The Critical Pitting Temperature (CPT) was measured with results according to the below table.

| Condition | Tensile strength, Rm, MPa | CPT, oC | CPT, oF |

| Annealed | 900 | >80 | >176 |

| Cold-rolled | 1600 | >80 | >176 |

| Cold-rolled and aged (480oC/3h) | 2000 | >80 | >176 |

Bending

The values given below have been obtained by bending according to Swedish standard SS 11 26 26 method 3 (in a 90° V-block with a 25 mm die opening, a sample of 35 mm width, turned so that the burrs of the blanked edges face into the bend). They can be used as guidance for the smallest recommended bending radius.

| Tensile strength | Thickness | Min bending radius, mm | |||

| MPa | ksi | mm | in. | ⊥ | // |

| 900 | 131 | 1.1 | 0.043 | 0.4t | 0.4t |

| 1550 | 225 | 0.50 | 0.020 | 0.8t | 13t |

| 1650 | 239 | 0.28 | 0.011 | 1.4t | 9t |

// Parallel to the rolling direction

⊥ Transverse to the rolling direction

t is short for thickness

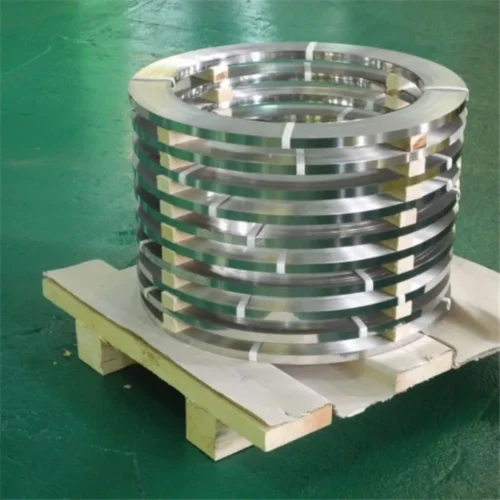

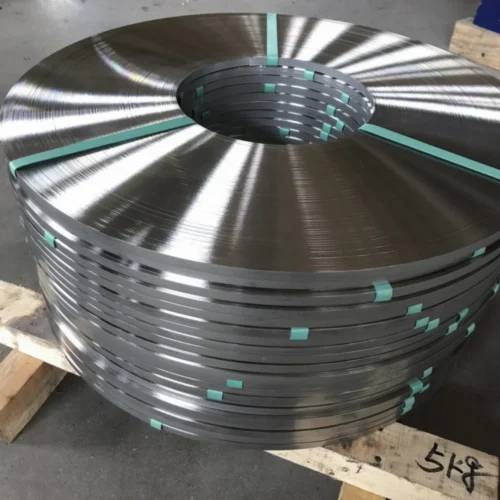

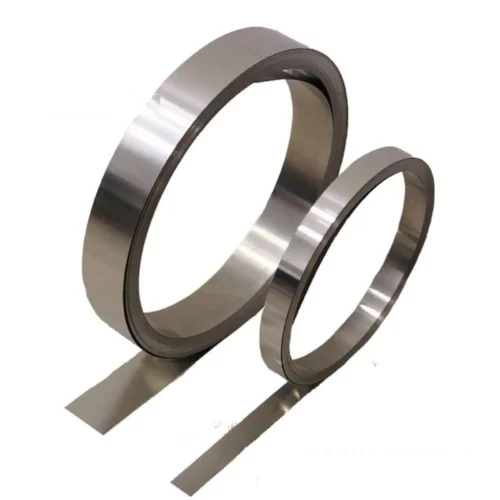

Forms of supply

The strip steel can be supplied in coils, bundles, on plastic spools or in lengths. The edges can be either slit, deburred or smoothly rounded.

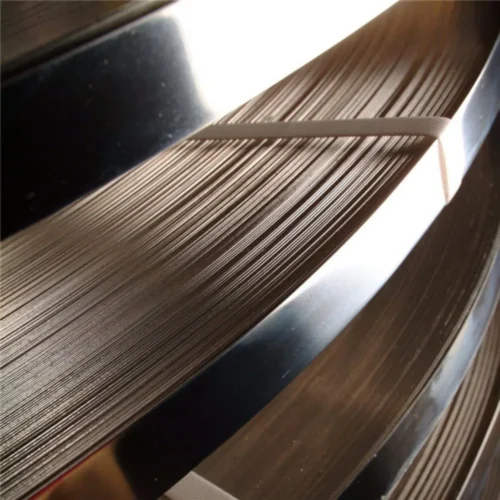

Conditions and dimensions

2507, S32750, 1.4410 is supplied in the solution annealed (bright annealed or annealed

and pickled) or cold rolled condition.

Width

2-300 mm (0.078-12 in.)

Thickness

0.015-3.5 mm (0.0006-0.14 in.)

Heat treatment

Solution annealing

The recommended annealing cycle is 1050-1125°C (1920-2060°F) for 1-5 minutes, followed by rapid cooling in air or water.

Aging

The strength of cold-rolled 2507, S32750, 1.4410 can be increased by a heat treatment operation at 480oC (900oF) for 3 h. An increase in tensile strength of 200-300 MPa and in proof strength of 400-500 MPa can be expected. Aging also increases the modulus of elasticity.

Aging is normally carried out after forming. If the aging is performed in an open-air furnace, a brownish oxide is formed on the surface. To avoid discoloration, parts should be carefully cleaned before heat treatment.

Mechanical properties

Static strength, nominal values at 20°C (68°F)

| Condition | Tensile strength, Rm | Proof strength, Rp0,2a) | Elongation, A11,3 | ||

| MPa | ksi | MPa | ksi | % | |

| A | 900 | 131 | 600 | 87 | 30 |

| C | 1150 | 167 | 1100 | 160 | 14 |

| C | 1350 | 196 | 1250 | 181 | 6 |

| C | 1550 | 225 | 1400 | 203 | 4 |

| CT | 1850 | 268 | 1800 | 261 | 3 |

| C | 1800 | 261 | 1550 | 225 | 3 |

- a) Rp0,2corresponds to 0.2% offset yield strength.

1 MPa = N/mm2

A = Annealed

C = Cold rolled

CT = Cold rolled and aged, 480°C (896°F)/3 h (see further under section “Heat treatment”.)

Fatigue strength

Nominal values at 20°C (68°F) in a normal dry atmosphere. The fatigue limit is defined as the stress at which 50% of the specimens withstand a minimum of 2 million load cycles.

Reversed bending stress

Average stress = 0

Bending transversal to rolling direction.

| Tensile strength, Rm | Fatigue limit, MPa | Tensile strength, Rm | Fatigue limit, ksi |

| Thickness, mm | Thickness, inch | ||

| MPa | 0,50 | ksi | 0.020 |

| 1850 | ± 540 | 268 | ± 78 |

Physical properties

The physical properties of a steel are related to a number of factors, including alloying elements, heat treatment and manufacturing process, but the following data can generally be used for rough calculations. The values refer to testing in the annealed condition at 20°C (68°F), where nothing else is mentioned.

Density: 7.8 g/cm3, 0.28 lb/in3

Thermal conductivity

| Temperature, °C | W/m °C | Temperature, °F | Btu/ft h°F |

| 20 | 16 | 68 | 9 |

| 100 | 17 | 200 | 9.5 |

| 200 | 19 | 400 | 11 |

| 300 | 20 | 600 | 11.5 |

| 400 | 21 | 750 | 12.5 |

Metric units, W/(m °C)

| Temperature, °C | 20 | 100 | 200 | 300 | 400 |

| 2507, S32750, 1.4410 | 14 | 15 | 16 | 18 | 20 |

| ASTM 316L | 14 | 15 | 17 | 18 | 20 |

Imperial units, Btu/(ft h °F)

| Temperature, °F | 68 | 200 | 400 | 600 | 800 |

| 2507, S32750, 1.4410 | 8 | 9 | 9 | 10 | 12 |

| ASTM 316L | 8 | 9 | 10 | 10 | 12 |

Specific heat capacity

| Temperature, °C | J/(Kg °C) | Temperature, °F | Btu/(lb °F) |

| 20 | 480 | 68 | 0.12 |

| 100 | 500 | 200 | 0.12 |

| 200 | 530 | 400 | 0.13 |

| 300 | 550 | 600 | 0.13 |

| 400 | 580 | 800 | 0.14 |

Thermal expansion

2507, S32750, 1.4410 has a coefficient of thermal expansion close to that of carbon steel. This gives 2507, S32750, 1.4410 definite design advantages over austenitic stainless steels in equipment comprising of both carbon steel and stainless steel. The values given below are average values in the temperature ranges.

Metric units 1)

| Temperature, °C | 30-100 | 30-200 | 30-300 | 30-400 |

| 2507, S32750, 1.4410 | 13 | 13.5 | 14 | 14.5 |

| Carbon steel (0.2%C) | 12.5 | 13 | 13.5 | 14 |

| ASTM 304L | 16.5 | 17.5 | 18 | 18 |

1) (x10-6/°C)

Imperial units 1)

| Temperature, °F | 86-200 | 86-400 | 86-600 | 86-750 |

| 2507, S32750, 1.4410 | 7 | 7.5 | 7.8 | 8 |

| Carbon steel (0.2%C) | 7 | 7 | 7.5 | 7.5 |

| ASTM 304L | 9.5 | 9.5 | 10 | 10 |

1) (x10-6/°F)

Modulus of elasticity, E 1)

| Condition | Tensile strength, Rm, MPa | E, MPa | Tensile strength, Rm, ksi | E, ksi |

| Cold rolled | 1550 | 180 | 225 | 26.1 |

| Cold rolled and aged | 1850 | 210 | 268 | 30.5 |

1) (x103)

Welding

The weldability of 2507, S32750, 1.4410 is good. Suitable welding methods are manual metal-arc welding with covered electrodes or gas shielded arc welding. Welding should be undertaken within the heat input range of 0.2-1.5 kJ/mm and with an interpass temperature of maximum 150°C (300°F).

Preheating or post-weld heat treatment is not necessary.

Matching filler metals are recommended in order to obtain a weld metal with optimum corrosion resistance and mechanical properties.