A693, S46910 spring stainless steel strip

A693, S46910 is a precipitation hardening, austenitic stainless steel specifically designed for applications requiring high strength and good ductility. Mechanical strength can be increased substantially by heat treatment (ageing) of the final product, after first taking advantage of a soft ‘as-delivered’ condition, favorable for forming.

Normally, strip steel in A693, S46910 is delivered in the cold rolled condition, but there is also a possibility of using the grade in the annealed condition and still reach a comparably high strength, solely by heat treatment.

A693, S46910 is characterized by:

- Very high tensile strength with comparably good ductility

- Very high ageing effect

- Hardenable by heat treatment from the annealed condition

- No softening after exposure to temperatures up to 450°C (842°F)

- Good weldability

Standards

- ASTM: A693

- UNS: S46910

Chemical composition (nominal)

Chemical composition (nominal) %

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | Ti | Al |

| ≤0.02 | ≤0.5 | ≤0.5 | ≤0.020 | ≤0.005 | 12 | 9 | 4 | 2.0 | 0.9 | 0.4 |

Applications

A693, S46910 is highly suitable for products requiring good corrosion resistance, high strength and good ductility in the final product, combined with high formability in the ‘as delivered’ condition. It is especially suitable for complicated designs that still have high requirements on the strength of the final product. It also provides an opportunity for reaching high strength levels in relatively heavy gauge components.

One suitable application is statically loaded springs, especially when a low relaxation at elevated temperatures is required. A693, S46910 is, however, less suitable for applications exposed to high dynamic stresses, as the same high fatigue strength as in an ordinary stainless spring steel, like Alleima® 12R11 (type ASTM 301), cannot be reached.

Corrosion resistance

A693, S46910 has better corrosion resistance than ASTM 304L. In this respect, it is superior to hardened and tempered martensitic chromium steels.

Bending

A693, S46910, because of the very high ageing effect, has good opportunities for forming in a soft condition and still reaching a high tensile strength in its final condition. This is illustrated by the diagrams in fig. 3-4. In fig. 3, the tensile strengths, necessary to reach the same final tensile strength of about 1850 MPa after ageing, are indicated for A693, S46910 and compared to some other Alleima grades. In fig. 4, a comparison of the bendability for the same materials in corresponding cold rolled tensile strengths is given.

The bending tests were carried out according to Swedish Standard SS 11 26 26 method 3, i.e. a test piece with a 35 mm width is bent in a 90° V-block with a 25 mm die opening, with the burrs from blanking, facing into in the bend. The minimum bending radius, without crack formation, for three test pieces is determined.

For very severe forming cases, the possibility of hardening A693, S46910 from the annealed condition might be an option, see section ‘Heat treatment’.

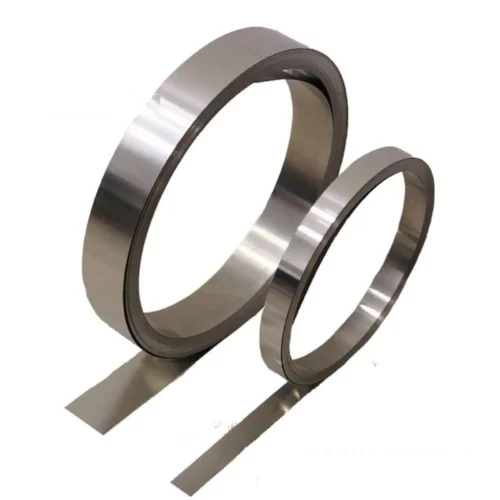

Forms of supply

Cold rolled strip can be supplied in coils, bundles, on spools or in cut lengths. Contact us for more informations.

The following range of thicknesses and widths can be supplied as standard. Contact us if other dimensions are required.

| Thickness | Width | Thickness | Width |

| mm | mm | in. | in. |

| 0.015 – 4.00* | 2 – 300 | 0.0006 – 0.158 | 0.079 – 11.8 |

* Depending on requested tensile strength.

Tolerances

The thickness and width tolerances are +/- tolerances to the nominal size. The normal tolerance classes for most of our strip products are T2 and B1. Tighter tolerances as well as other tolerance limits can be offered upon request.

Mechanical properties

Static strength

The possible ranges for the mechanical properties, in both the cold rolled and aged conditions are indicated below. The strength level after ageing depends on the degree of cold deformation and, therefore, also on the dimension. For more information regarding ageing, see section ‘Heat treatment’.

At 20°C (68°F), nominal values

| Condition | Proof strength | Tensile strength | ||

| Rp0.2a) | Rm | |||

| MPa | ksi | MPa | ksi | |

| Annealed | max. 350 | max. 51 | max. 750 | max. 109 |

| Cold rolled | 600-1800 | 87-261 | 950-1850 | 138-268 |

| Cold rolled + Aged | 1200-2500 | 174-363 | 1400-2600 | 203-377 |

1 MPa = 1 N/mm2

a) Rp0.2 corresponds to 0.2% offset yield strength.

At high temperatures, nominal values

The values represent testing on material cold worked to 1650 MPa and subsequently aged at 475°C (887°F) for 4 hours.

| Temperature | Tensile strength, Rm | Temperature | Tensile strength, Rm |

| °C | MPa | °F | ksi |

| 20 | 2450 | 68 | 356 |

| 100 | 2400 | 200 | 348 |

| 200 | 2200 | 400 | 319 |

| 300 | 2125 | 600 | 308 |

| 400 | 1975 | 700 | 287 |

Fatigue strength

A693, S46910 has a comparably good fatigue strength at low tensile strengths. The tables show nominal results of testing at 20°C (68°F) after ageing at 475°C (887°F) for 4 hours. The fatigue strength represents a 50% probability of failure after 2 million cycles, with specimens parallel to the rolling direction.

Reversed bending stress

Average stress = 0

Bending transversal to rolling direction.

| Tensile strength, Rm | Thickness | Fatigue strength, σu | σu/ Rm | |

| MPa | mm | MPa | ||

| Cold rolled | Aged | |||

| 1025 | 1600 | 0.30 | ± 490 | 0.31 |

| 1230 | 2000 | 0.50 | ± 450 | 0.23 |

| 1450 | 2200 | 0.50 | ± 500 | 0.23 |

| 1500 | 2350 | 0.50 | ± 450 | 0.19 |

Fluctuating tensile stress

Minimum stress = 0

Specimens parallel to rolling direction.

| Tensile strength, Rm | Thickness | Fatigue strength, σu | σu/ Rm | |

| MPa | mm | MPa | ||

| Cold rolled | Aged | |||

| 1000 | 1470 | 0.30 | 370 ± 370 | 0.25 |

Physical properties

The physical properties of a steel relate to a number of factors, including alloying elements, heat treatment and manufacturing process, but the following data can generally be used for rough calculations. The values refer to testing at 20°C (68°F), unless otherwise stated.

Density: 7.9 g/cm3, 0.29 lb/in3

Resistivity: 0.9 μΩm, 35 μΩin.

Thermal conductivity for material in the aged condition

| Temperature, °C | W/m °C | Temperature, °F | Btu/ft h°F |

| 20 | 14 | 68 | 8 |

| 100 | 16 | 200 | 9 |

| 200 | 18 | 400 | 10.5 |

| 300 | 20 | 600 | 11.5 |

| 400 | 21 | 700 | 12 |

Specific heat capacity for material in the aged condition

| Temperature, °C | J/kg °C | Temperature, °F | Btu/ft h°F |

| 20 | 455 | 68 | 0.11 |

| 100 | 490 | 200 | 0.12 |

| 200 | 525 | 400 | 0.13 |

| 300 | 560 | 600 | 0.14 |

| 400 | 600 | 700 | 0.14 |

Thermal expansion, average values in temperature ranges

A693, S46910 has a coefficient of thermal expansion close to that of carbon steel. This gives it definite design advantages over other austenitic stainless steels.

Metric units, (x10-6/°C)

| Grade | Temperature range, °C | |||

| 30-100 | 30-200 | 30-300 | 30-400 | |

| Nanoflex (cold rolled) | 11.5 | 11.5 | 11.5 | 11.5 |

| Nanoflex (aged) | 11.5 | 12 | 12 | 12.5 |

| Carbon steel (0.2%C) | 12.5 | 13 | 13.5 | 14 |

| ASTM 304L | 16.5 | 17.5 | 18 | 18 |

Imperial units, (x10-6/°F)

| Grade | Temperature range, °F | |||

| 86-200 | 86-400 | 86-600 | 86-700 | |

| Nanoflex (cold rolled) | 6.5 | 6.5 | 6.5 | 6.5 |

| Nanoflex (aged) | 6.5 | 6.5 | 7 | 7 |

| Carbon steel (0.2%C) | 7 | 7 | 7.5 | 7.5 |

| ASTM 304L | 9.5 | 9.5 | 10 | 10 |

Modulus of elasticity

The E-modulus is dependent on dimension, condition, direction and amount of cold reduction of the material.

The data below has been achieved by tensile testing cold rolled strip at 20°C (68°F) along the rolling direction. They are typical values only. After ageing, an increase of the E-modulus by 15-20×103 MPa can be expected.

| Tensile strength | E (x103) | Tensile strength | E (x103) |

| MPa | MPa | ksi | ksi |

| 1000 | 185 | 145 | 26.8 |

| 1200 | 180 | 174 | 26.1 |

| 1450 | 185 | 210 | 26.8 |

| 1850 | 190 | 268 | 27.6 |

Heat treatment

In the annealed condition, A693, S46910 has an austenitic microstructure. To be able to precipitation harden the material and take advantage of the remarkably high ageing (tempering) effect, the matrix has first to be hardened and, thereby, partly transformed to martensite. There are two ways of obtaining the necessary martensitic matrix in A693, S46910.

Cold rolled condition:

The most common way, as in other metastable austenitic stainless steels, is to cold roll the material, whereby deformation martensite is formed. The difference is that the ageing effect is much higher in A693, S46910 than in most other stainless steels. For optimum strength, the ageing should be made at 525°C (977°F) for 1 hour. Some examples of the ageing effect are given in the table.

Nominal values at 20°C (68°F)

| Tensile strength | Tensile strength, | ||

| MPa | ksi | ||

| Cold rolled | Aged | Cold rolled | Aged |

| 950 | 1300 | 138 | 189 |

| 1000 | 1600 | 145 | 232 |

| 1200 | 2000 | 174 | 290 |

| 1500 | 2300 | 218 | 334 |

| 1800 | 2500 | 261 | 363 |

Annealed condition:

With A693, S46910 there is another way to obtain a martensitic matrix – by an isothermal treatment at a subzero temperature. This gives an opportunity to use the grade in the soft annealed condition for severe cases of forming and then utilize its ability to still reach a comparably high level of hardness after heat treatment. The required heat treatment cycle and the resulting properties are:

Austenitizing: 1200°C (2190°F) for 5 minutes in a protective atmosphere like argon, hydrogen or vacuum.

Isothermal treatment: -40°C (-40°F) for 24 hours

Ageing: 525°C (997°F) for 1 hour

Nominal values at 20°C (68°F)

| Tensile strength | Tensile strength | ||

| MPa | ksi | ||

| Annealed | Heat treated | Annealed | Heat treated |

| 700 | 1600 | 102 | 232 |

Welding

The weldability of A693, S46910 is good. Appropriate welding methods are TIG and laser welding. It can be welded without filler metal (autogenously) using the TIG process or laser process, but filler metal is preferable. Suitable fillers are according to standard ISO 14343: 19 12 3 L Si; AWS A5.9/ASME SFA-5.9: ER316LSi; W.Nr.: 1.4430 and ISO 14343: 19 12 3 L; AWS A5.9/ASME SFA-5.9: ER316L; W.Nr.: 1.4430 or ISO 14343: 22 9 3 N L; AWS A5.9/ASME SFA-5.9: ER2209; W.Nr.: 1.4462.

The martensite content in the heat-affected zone (HAZ) of the material decreases after welding, resulting in a typical, annealed microstructure with an austenitic matrix and a small amount of ferrite. This means that the tensile strength will be lower for the weld compared with the high strength base material, in the same way as other cold rolled austenitic stainless steels. Therefore, welds in A693, S46910 are not suitable for active parts of a construction, where a high stress level has to be managed.