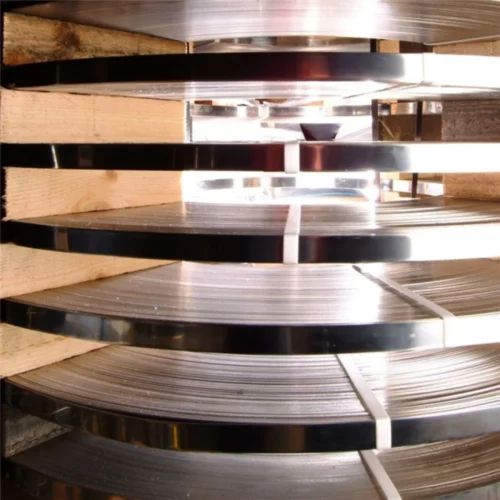

Alloy 360, TD01, N03360, Nibry, Nickel Alloy Strip

Beryllium Nickel 360 is a Beryllium-Nickel alloy capable of high strength through precipitation heat treatment. The excellent spring characteristics to 550°F make it suitable for many of the most demanding electromechanical devices.

The alloy can be readily formed and even deep drawn from the annealed temper. Cold rolled tempers prior to heat treatment can be blanked and folded provided a radius to thickness ratio approaches 2.0.

The optimum heat treatment for highest strength is 925ºF for 2 hours. The material can be joined using conventional TIG methods, silver brazed and soldered.

Available Sizes:

Beryllium Nickel 360 is available as strip product in thicknesses from 0.0005” to 0.025” in (0.0127 to 0.635 mm) widths up to 7.0” (177.8 mm). A foil product is available as thin as 0.000085” (0.002159 mm) and widths of 4.0” (101.6 mm) maximum. The material conforms to UNS N03360.

Nominal Composition

| Beryllium Nickel 360 NOMINAL COMPOSITION | |

| Beryllium | 1.90% |

| Titanium | 0.50% |

| Nickel | Balance |

Mechanical Properties

| Beryllium Nickel 360 MECHANICAL PROPERTIES | |||

| ANNEALED | COLD ROLLED | COLD ROLLED HEAT TREATED |

|

| Ultimate Tensile Strength | 100,000 PSI | 190,000 PSI | 270,000 PSI |

| Yield Strength | 50,000 PSI | 180,000 PSI | 250,000 PSI |

| Elongation in 2” * | 30% | 1% | 2% |

| Modulus of Elasticity (Tension) | 28.5 X106 PSI | ||

| Poisson’s Ratio | 0.295 | ||

*The measured elongation will be less as thickness decreases to 0.002” and less.

Physical Properties

| Beryllium Nickel 360 PHYSICAL PROPERTIES | |

| Density | 0.309 lbs/cu.in. |

| Melting Point (Approx.) | 1185°C |

| Electrical Resistivity @ R.T. Cold Rolled Heat Treated |

43.1 Microhm·cm 28.7 Microhm·cm |

| Thermal Expansion Coefficient (25° to 550°C) | 14.4 X 10-6/°C |

| Thermal Conductivity @ R.T | 48.4 W/m·K |

| Magnetic Attraction | Yes |

Typical values to guide alloy selection but are not a guarantee of minimum or maximum.