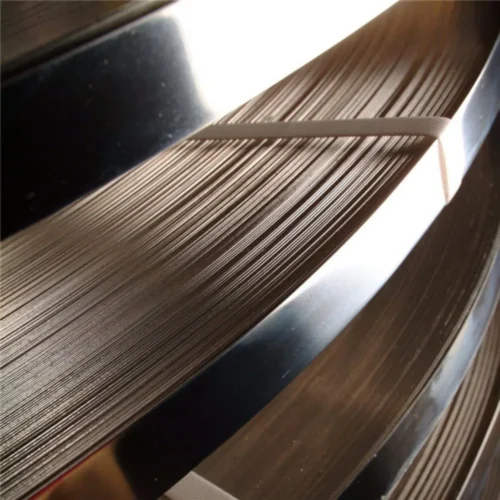

C55S, 1.1204, CK55, 1.1203, Spring Steel Strip

C55S properties and heat treatment, Including C55S application and specifications, We have all specifications,Including C55S steel plate, C55S sheet, we can own production and sales. One of the most widely used precipitation hardening grades in the business. While soft and ductile in the solution annealed condition, it is capable of high properties with a single precipitation or aging treatment. Characterized by good corrosion resistance, high harness, toughness and strength. Whether its for wear parts, springs, chain links or safety components, heat treatable steels offer the right solution for all requirements. Good fine blanking properties and formability in the annealed condition are combined with high strengths and good toughness in the quenched and tempered condition. Close analysis ranges tailored to specific purposes and precisely controlled rolling parameters guarantee consistent and outstanding processability and consistent heat treatment results.

Dimensions

Thickness: 0.1 to 10mm

Width: 10 to 1500mm

*accept nonstandard size, please contact with our sales.

Chemical composition

| C | Si | Mn | P max. | S max. | Cr | Mo max. | Ni |

| 0,52 to 0,60 | 0,15 to 0,35 | 0,60 to 0,90 | 0,025 | 0,025 | max. 0,40 | 0,10 | max. 0,40 |

Mechanical properties

| annealed (+A) or annealed and skin passed (+LC) | cold rolled (+CR) | quenched and tempered (+QT) | |||||

| Proof strength max. Mpa | Tensile strength max. Mpa | Elongation % min. | HV max. | Tensile strength max. Mpa | HV max. | Tensile strength Mpa | HV |

| 480 | 600 | 17 | 185 | 1070 | 300 | 1 100 to 1 700 | 340 to 520 |

Delivery condition

-annealed or annealed and skin passed(+A or +LC);

-cold rolled(+CR);

-quenched and tempered(+QT).

Surface finish

1 Grey/blue oxide finish:unpolished;

2 bright tempered:unpolished

3 polished

4 polished and coloured:blue or yellow colour

Inspection and testing

verification of the dimensions

visual examination of the surface quality

Chemical analysis

Extent of testing

Tensile and bending tests

Tolerances on shape