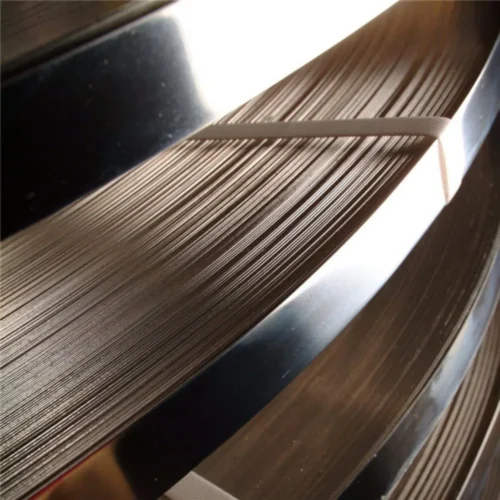

C60S, 1.1211, CK67, 1.221, Spring Steel Strip

C60S 1.1211 belongs to the class of quenched tempered spring steel strip. Thanks to his patented homogeneous structure and his tight tolerances this steel is often used for instrument making. Other applications include various types of springs with high tensile strength as a function of the diameter. Corrosion resistance: A carbon steel has no natural resistance to corrosion in the usual sense. He must be protected as required with an appropriate procedure before general corrosion. Heat treatment: By +QT it receives its application for the typical microstructure.

Dimensions

Thickness: 0.1 to 10mm

Width: 10 to 1500mm

*accept nonstandard size, please contact with our sales.

Chemical composition

| name | number | C | Si | Mn | P max. | S max. | Cr | Mo max. | Ni |

| C60S | 1.1211 | 0,57 to 0,65 | 0,15 to 0,35 | 0,60 to 0,90 | 0,025 | 0,025 | max. 0,40 | 0,10 | max. 0,40 |

Mechanical properties

| Steel designation | delivery condition | ||||||||

| annealed (+A) or annealed and skin passed (+LC) | cold rolled (+CR) | quenched and tempered (+QT) | |||||||

| name | number | Proof strength max. Mpa | Tensile strength max. Mpa | Elongation % min. | HV max. | Tensile strength max. Mpa | HV max. | Tensile strength Mpa | HV |

| C60S | 1.1211 | 495 | 620 | 17 | 195 | 1100 | 305 | 1 150 to 1 750 | 345 to 530 |

Delivery condition

-annealed or annealed and skin passed(+A or +LC);

-cold rolled(+CR);

-quenched and tempered(+QT).

Surface finish

1 Grey/blue oxide finish:unpolished;

2 bright tempered:unpolished

3 polished

4 polished and coloured:blue or yellow colour

Inspection and testing

verification of the dimensions

visual examination of the surface quality

Chemical analysis

Extent of testing

Tensile and bending tests

Tolerances on shape