C67S, CK67, 1.1231, Spring Steel Strip

Material No.: C67S 1.1231 German standard: DIN EN 10132 International steel grades: SAE:1070 JIS: S70CM Unalloyed steel for springs as belleville washers, spring plates and stabilizer bars for motor vehicles Hot forming and heat treatment: Forging or hot rolling: Normalising: Soft annealing: Hardening: 1100 – 800°C 810 – 840°C/air 680 – 710°C/furnace 815 – 845°C/oil min. 59 HRC or 670 HV as quenched

Dimensions

Thickness: 0.1 to 10mm

Width: 10 to 1500mm

*accept nonstandard size, please contact with our sales.

Chemical composition

| name | number | C | Si | Mn | P max. | S max. | Cr | Mo max. | Ni |

| C67S | 1.1231 | 0,65 to 0,73 | 0,15 to 0,35 | 0,60 to 0,90 | 0,025 | 0,025 | max. 0,40 | 0,10 | max. 0,40 |

Mechanical properties

| Steel designation | delivery condition | ||||||||

| annealed (+A) or annealed and skin passed (+LC) | cold rolled (+CR) | quenched and tempered (+QT) | |||||||

| name | number | Proof strength max. Mpa | Tensile strength max. Mpa | Elongation % min. | HV max. | Tensile strength max. Mpa | HV max. | Tensile strength Mpa | HV |

| C67S | 1.1231 | 510 | 640 | 16 | 200 | 1140 | 315 | 1 200 to 1 900 | 370 to 580 |

Delivery condition

-annealed or annealed and skin passed(+A or +LC);

-cold rolled(+CR);

-quenched and tempered(+QT).

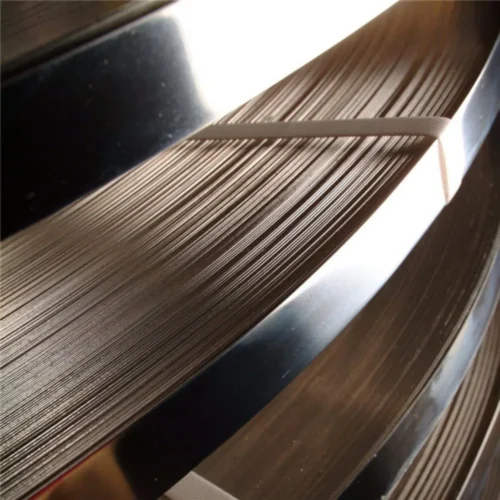

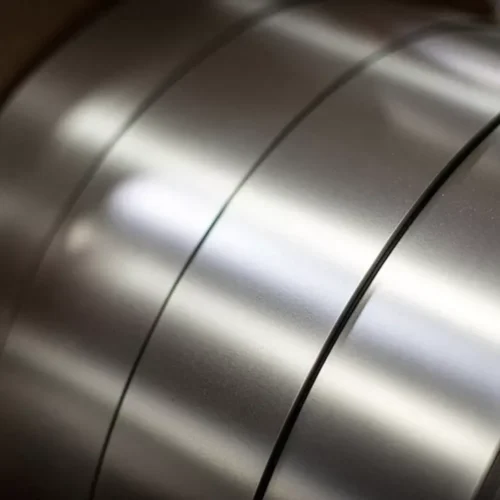

Surface finish

1 Grey/blue oxide finish:unpolished;

2 bright tempered:unpolished

3 polished

4 polished and coloured:blue or yellow colour

Inspection and testing

verification of the dimensions

visual examination of the surface quality

Chemical analysis

Extent of testing

Tensile and bending tests

Tolerances on shape