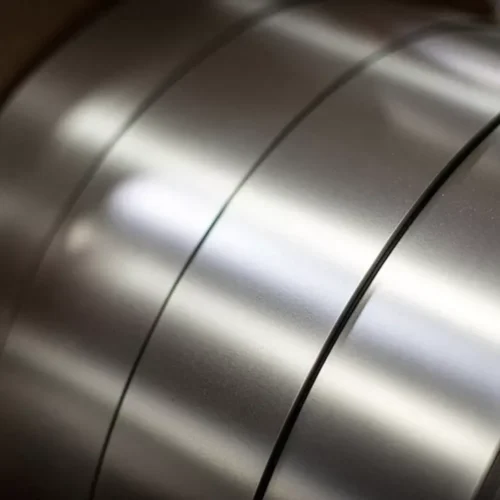

C85S, CK85, 1.1269, Spring Steel Strip

C85S, 1.1269, AISI 1086, CK85 is non-alloyed carbon structural steel with low hardening capacity for oil hardening for low-duty, periodically operating springs, springs and spring elements, immune to the temper brittleness. It is characterized by its high hardness and abrasion resistance, while maintaining high strength. It is used for flat and spiral springs, machine parts or saws of all kinds for cutting.

Dimensions

Thickness: 0.1 to 10mm

Width: 10 to 1500mm

*accept nonstandard size, please contact with our sales.

Chemical composition

| name | number | C | Si | Mn | P max. | S max. | Cr | Mo max. | Ni |

| C85S | 1.1269 | 0,80 to 0,90 | 0,15 to 0,35 | 0,40 to 0,70 | 0,025 | 0,025 | max. 0,40 | 0,10 | max. 0,40 |

Mechanical properties

| Steel designation | delivery condition | ||||||||

| annealed (+A) or annealed and skin passed (+LC) | cold rolled (+CR) | quenched and tempered (+QT) | |||||||

| name | number | Proof strength max. Mpa | Tensile strength max. Mpa | Elongation % min. | HV max. | Tensile strength max. Mpa | HV max. | Tensile strength Mpa | HV |

| C85S | 1.1269 | 535 | 670 | 15 | 210 | 1190 | 325 | 1 200 to 2 000 | 370 to 600 |

Delivery condition

-annealed or annealed and skin passed(+A or +LC);

-cold rolled(+CR);

-quenched and tempered(+QT).

Surface finish

1 Grey/blue oxide finish:unpolished;

2 bright tempered:unpolished

3 polished

4 polished and coloured:blue or yellow colour

Inspection and testing

verification of the dimensions

visual examination of the surface quality

Chemical analysis

Extent of testing

Tensile and bending tests

Tolerances on shape