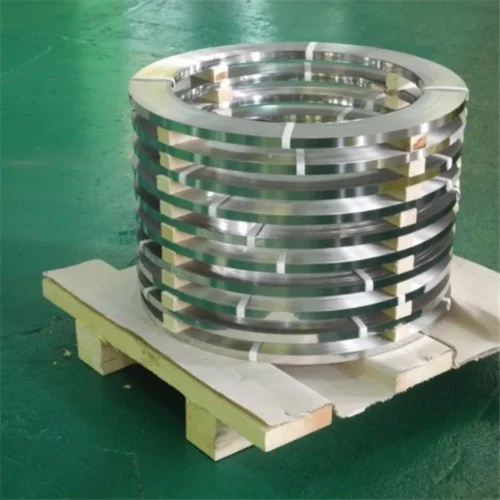

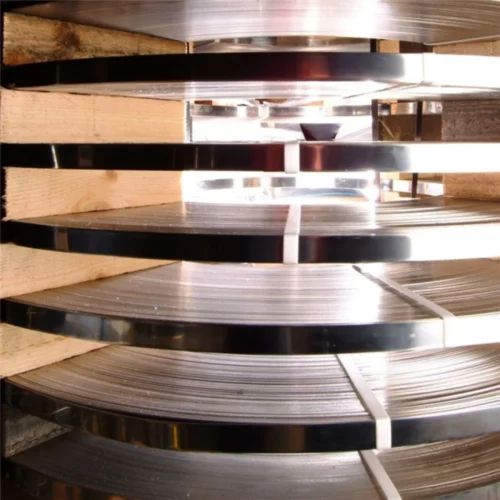

Inconel 625, N06625, 2.4856, Nickel Alloy Strip

Inconel 625 is a nickel-chromium-molybdenum alloy with niobium which is well suited for a wide range of severe corrosive environments. The alloy composition provides a product which performs well at elevated temperatures up to 1800°F. The strength can be increased by cold working.

The alloy is readily formed in the annealed temper, and can be joined by the standard welding and brazing processes.

Available Sizes:

Inconel 625 is available as strip product in thicknesses from 0.001” to 0.025” (0.0254 mm to 0.635 mm) in widths up to 12.0” (304.8 mm). The material conforms to ASTM B443, AMS 5599 and UNS N06625.

We can also supply product to AMS 5879 (UNS N06626) for demanding fatigue applications, which incorporates double melting, and restrictive limits for Carbon and Nitrogen.

Nominal Composition

| Inconel 625 NOMINAL COMPOSITION | |

| Chromium | 22.0% |

| Nickel | 61.0% |

| Iron | 4% |

| Niobium | 3.5% |

| Molybdenum | 9.0% |

Mechanical Properties

| Inconel 625 MECHANICAL PROPERTIES | ||

| ANNEALED | COLD ROLLED | |

| Ultimate Tensile Strength | 135,000 PSI | 180,000 PSI |

| Yield Strength (0.2% Offset) | 75,000 PSI | 160,000 PSI |

| Elongation in 2” * | 45% | 2% |

| Modulus of Elasticity (Tension) | 30 X 106 PSI | – |

| Poisson’s Ratio | 0.28 | – |

*The measured elongation will be less as thickness decreases to 0.002” and less.

Physical Properties

| Inconel 625 PHYSICAL PROPERTIES | |

| Density | 0.305 lbs./cu.in. |

| Melting Point (Approx.) | 1290°C |

| Electrical Resistivity @ R.T | 129 Microhm·cm |

| Temperature Coefficient of Resistivity (20° to 100°C) | 13.3 x 10-6/ °C |

| Thermal Conductivity @ R.T | 9.8 W/m·K |

| Curie Temperature | < – 196°C |

| Magnetic Permeability at 200 Oe | 1.0006 |

| Magnetic Attraction | None |

Typical values to guide alloy selection but are not a guarantee of minimum or maximum.