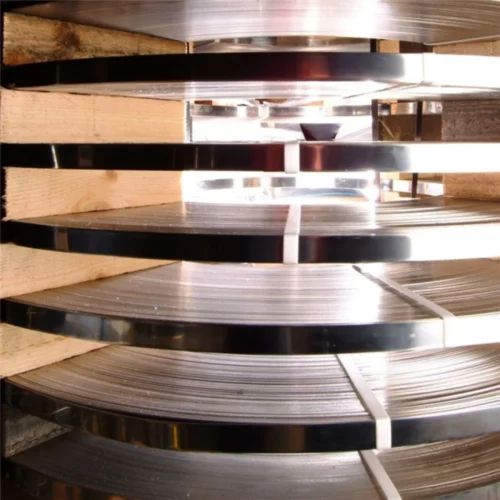

Monel 400, N04400, 2.4360, Nickel Alloy Strip

Monel 400 is a Nickel-Copper alloy with excellent corrosion resistant characteristics in marine environments.

The alloy is readily formed from the annealed temper. It is easy to fabricate by conventional welding techniques.

Available Sizes:

Monel 400 is available as strip product in thicknesses from 0.0005” to 0.050” (0.0127 mm to 1.27 mm) and widths up to 12.0” (304.8 mm). The material conforms to ASTM B127 and UNS N04400.

Nominal Composition

| Monel 400 NOMINAL COMPOSITION | |

| Nickel | 65.0% |

| Copper | 32.0% |

| Iron | 1.5% |

| Manganese | 1.0% |

| Carbon | 0.01% |

Mechanical Properties

| Monel 400 MECHANICAL PROPERTIES | ||

| ANNEALED | COLD ROLLED | |

| Ultimate Tensile Strength | 75,000 PSI | 120,000 PSI |

| Yield Strength (0.2% Offset) | 30,000 PSI | 100,000 PSI |

| Elongation in 2” * | 35% | 2% |

| Modulus of Elasticity (Tension) | 26 X 106 PSI | – |

| Poisson’s Ratio | 0.32 | – |

*The measured elongation will be less as thickness decreases to 0.002” and less.

Physical Properties

| Monel 400 PHYSICAL PROPERTIES | |

| Density | 0.319 lbs./cu.in. |

| Melting Point (Approx.) | 1300°C |

| Electrical Resistivity @ R.T. | 51 Microhm·cm |

| Temperature Coefficient of Resistivity (25° to 100°C) | 13.9 x 10-6/°C |

| Thermal Conductivity @ R.T. | 21.8 W/m·K |

| Magnetic Attraction | None |

| Curie Temperature | 10°C |

Typical values to guide alloy selection but are not a guarantee of minimum or maximum.