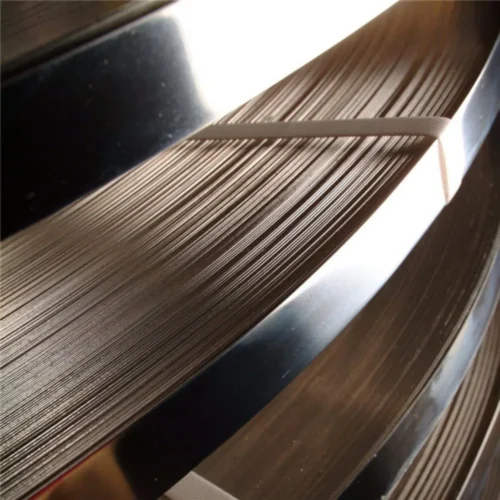

N07750 spring nickel alloy strip

N07750 is a precipitation hardening nickel alloy with good spring properties and good resistance to gas corrosion at high temperatures. Due to the grade’s low cobalt content, N07750 is particularly suitable for nuclear power applications.

Standards

- UNS: N07750

Chemical composition (nominal)

Chemical composition (nominal) %

| C | Si | Mn | P | S | Cr | Ni |

| ≤0.030 | 0.3 | 0.6 | ≤0.015 | ≤0.010 | 16 | 72 |

Others: Fe=7.0 Al=0.7 Ti=2.5 Nb=0.8

Mechanical properties

Static strength

Nominal values at 20°C (68°F)

| Condition1) | Tensile strength, Rm | Proof strength, Rp0,2a) | Elongation, A11,3 | ||

| MPa | ksi | MPa | ksi | % | |

| A | 800 | 116 | 340 | 49 | 52 |

| AT | 1210 | 176 | 810 | 118 | 27 |

1) A = Annealed, AT = Annealed and tempered, 705°C (1300°F)/20 h

- a) R2corresponds to 0.2% offset yield strength.

1 MPa = 1 N/mm2

Physical properties

Density: 8.3 g/cm3, 0.30 lb/in3

Specific heat capacity

| 420 – 460 J/kg °C | in the temperature range 20 – 100°C |

| 540 J/kg °C | in the temperature range 50 – 900°C |

| Temperature, °C | W/m °C | Temperature, °F | Btu/ft h °F |

| 100 | 16.3 | 210 | |

| 300 | 19.8 | 570 | |

| 500 | 25.6 | 930 | |

| 700 | 30.2 | 1 290 | |

| 900 | 37.2 | 1 650 |

Resistivity

| Temperature, °C | μΩm | Temperature, °F | μΩin. |

| 20 | 1.20 | 70 | |

| 100 | 1.25 | 210 | |

| 200 | 1.25 | 390 | |

| 300 | 1.25 | 570 | |

| 500 | 1.30 | 930 | |

| 700 | 1.30 | 1 290 |

Thermal expansion, mean values in temperatur ranges ( x10-6)

| Temperature, °C | per °C | Temperature, °F | per °F |

| 30 – 100 | 12.2 | 85 – 210 | |

| 30 – 300 | 13.4 | 85 – 570 | |

| 30 – 500 | 13.8 | 85 – 930 | |

| 30 – 700 | 14.9 | 85 – 1 290 | |

| 30 – 900 | 16.5 | 85 – 1 650 |

Permeability, mmax: 1.004