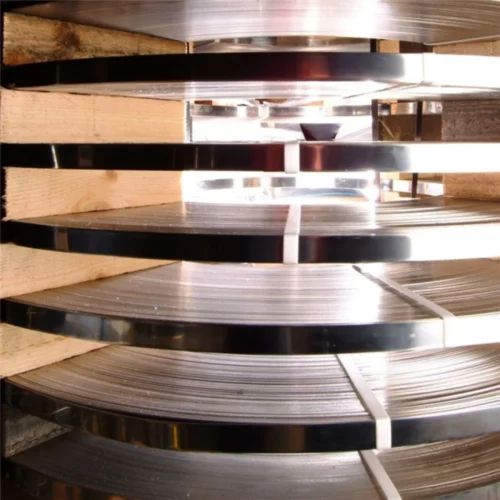

Nickel 233, N02233, 2.4060, Nickel Alloy Strip

Nickel 233 is a commercially pure wrought Nickel with low carbon. The material has excellent corrosion resistance with high thermal and electrical conductivities. A high thermal coefficient of electrical resistance makes it suitable for temperature sensors, and electronic components.

The alloy can be formed by all conventional cold-forming methods and can be joined by welding, brazing and soldering. The corrosion resistance is generally very good in most mediums, although it is subject to intergranular embrittlement by sulfur compounds above 315°C.

Available Sizes:

Nickel 233 is available as strip product in thicknesses from 0.0005” to 0.020” (0.0127 mm to 0.508 mm) in widths up to 12.0” (304.8 mm). It is available as foil as thin as 0.000100” (0.00254 mm) in 4.0” (101.6 mm) maximum width. The material conforms to ASTM B162, ASTM F3, and UNS N02233.

Nominal Composition

| Nickel 233 NOMINAL COMPOSITION | |

| Nickel | 99.7% |

| Manganese | 0.1% |

| Iron | 0.05% |

| Carbon | 0.01% |

Mechanical Properties

| Nickel 233 MECHANICAL PROPERTIES | ||

| ANNEALED | COLD ROLLED | |

| Ultimate Tensile Strength | 55,000 PSI | 110,000 PSI |

| Yield Strength (0.2% Offset) | 15,000 PSI | 100,000 PSI |

| Elongation in 2” * | 40% | 2% |

| Modulus of Elasticity (Tension) | 30 X 106 PSI | – |

| Poisson’s Ratio | 0.28 | – |

The measured elongation will be less as thickness decreases to 0.002” and less

Physical Properties

| Nickel 233 PHYSICAL PROPERTIES | |

| Density | 0.321 lbs./cu.in. |

| Melting Point (Approx.) | 1445°C |

| Electrical Resistivity @ R.T. | 7.7 Microhm·cm |

| Temperature Coefficient of Resistivity (20° to 95°C) | 5500 PPM/°C |

| Thermal Expansion Coefficient (20° to 100°C) | 13.3 X 10-6 /°C |

| Thermal Conductivity @ R.T. | 80.7 W/m·K |

| Curie Temperature | 350°C |

| Magnetic Attraction | Yes |

Typical values to guide alloy selection but are not a guarantee of minimum or maximum.