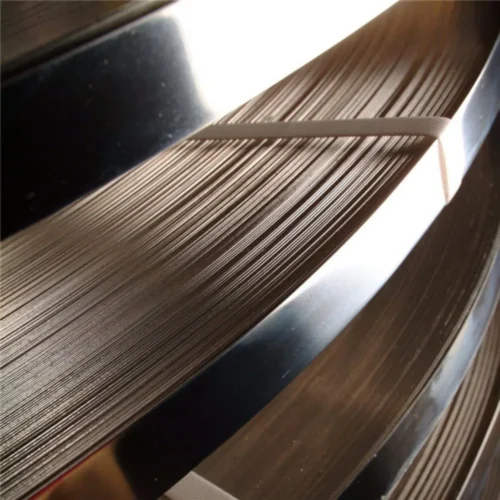

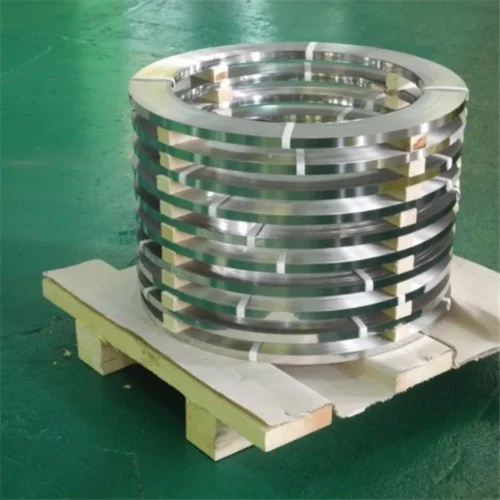

S42026, 1.4031 knife steel strip

S42026, 1.4031 is a martensitic stainless steel alloyed with molybdenum that is characterized by good formability. After hardening, the grade has:

Very good corrosion resistance

High toughness

Excellent fatigue strength

S42026, 1.4031 is typically used for cutters in electric shavers and springs.

Standards

- UNS: S42026

- EN Number: (1.4031)*

*) Nearest equivalent grade

Chemical composition (nominal)

Chemical composition (nominal) %

| C | Si | Mn | P | S | Cr | Mo |

| 0.38 | 0.4 | 0.6 | ≤0.025 | ≤0.010 | 13.5 | 1.0 |

Forms of supply

Strip can be supplied either in coils or as straightened lengths of 0.5 – 4.0 meters (1.6 – 13.1 feet). The coil weight is max. 5 kg/mm (280 lbs/in.) of strip width.

Hardening and tempering of the strip steel is needed to achieve the correct finish and to meet the properties required by the end-user.

Dimensions

| Thickness | Width | ||

| mm (in.) | mm (in.) | ||

| Min. | Max | Min. | Max. |

| 0.10 (0.0039) | 4.5 (0.177) | 5 (0.197) | 350 (13.78) |

Other sizes can be supplied to meet specific requirements.

Tolerances

The thickness and width tolerances are +/- tolerances to the nominal size. The normal tolerance classes for most of our strip products are T2 and B1. Tighter tolerances as well as other tolerance limits can be offered upon request.

Mechanical properties

| As-delivered | Tensile strength | Hardness | |

| MPa (ksi) | HV | HRB | |

| Annealed | max. 700 (102) | max. 215 | max. 94.3 |

| Cold rolled | 850-1000 (123-145) | 265-315 | 101.4-106.6 |

Physical properties

The physical properties of a steel are related to a number of factors, including alloying elements, heat treatment and manufacturing route, but the data presented below can generally be used for rough calculations.

| Density | |

| g/cm3 | 7.7 |

| lb/in.3 | 0.28 |

Heat treatment

Hardening data

Hardening temperature 1030°C (1885°F), strip thickness 3.5 mm (0.138 in.), holding time 6 minutes, quenching in oil.

Tempering data

Tempering time 30 minutes.