19+

Year production experience

1000000+

Tons year capacity

200+

Professional staff

169+

Customer’s country

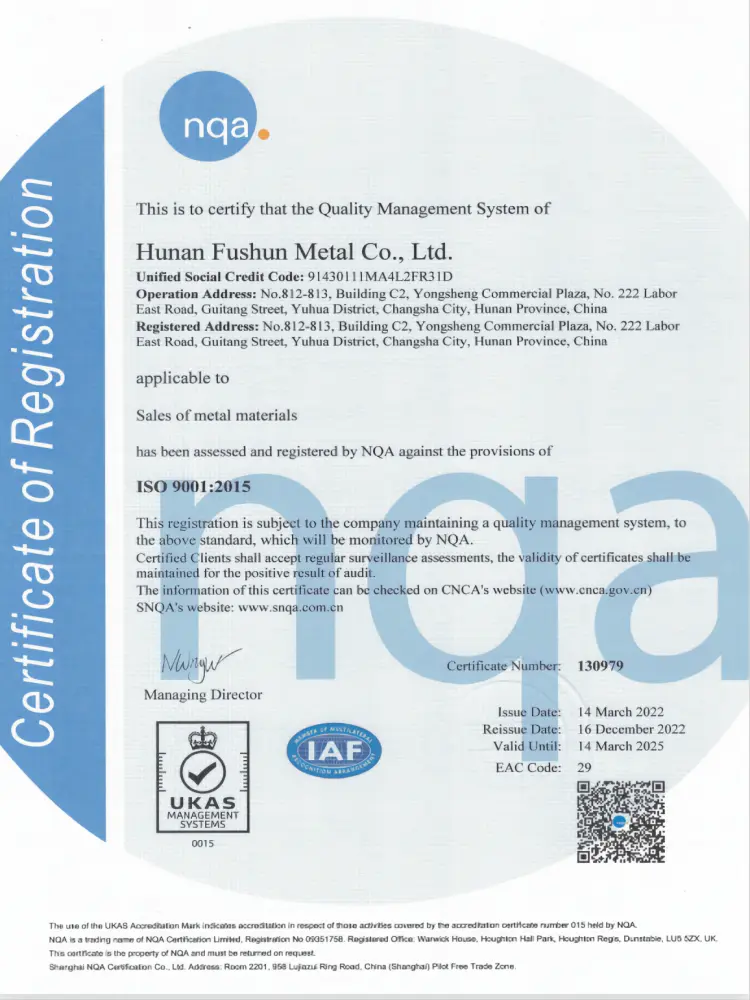

Quality Management System

Our company adheres to a stringent quality control system, ensuring that every aspect of our production process meets the highest standards. We are proud to have obtained the ISO NQA9001 certification, which underscores our commitment to maintaining excellence in our quality management practices.

Our state-of-the-art laboratory is equipped with advanced testing facilities to perform a wide range of analyses. We conduct thorough chemical composition analysis to verify the elemental makeup of our steel, ensuring it meets the required specifications. Our tensile testing capabilities allow us to assess the strength and ductility of our steel strips, ensuring they can withstand the demands of their intended applications.

In addition to these tests, we perform hardness testing to determine the steel’s resistance to deformation and ensure it meets the necessary hardness criteria. Precise dimensional measurements are conducted to guarantee that the steel strips conform to the exact size specifications provided by our customers. Surface roughness evaluation is also carried out to ensure a smooth finish, which is critical for many high-end applications.

Our Certificates

Let Us Strictly Manage Your Order

Dimensional Control

At our company, we meticulously manage your orders to ensure precise dimensional control. Utilizing advanced cold rolling processes, we achieve exceptional accuracy and uniformity in our steel strips. The cold rolling technique involves passing the steel through a series of rollers at room temperature, which compresses and elongates the material, resulting in a precise and consistent thickness. This method allows us to produce steel strips with tight tolerances and minimal deviations, ensuring that every piece meets the exact specifications required by our customers. Our commitment to dimensional accuracy guarantees that the steel strips will fit perfectly in their intended applications, providing reliable performance and ease of use.

Mechanical Properties

We place a strong emphasis on the mechanical properties of our steel strips, employing advanced heat treatment processes to enhance their performance. Through techniques such as annealing, quenching, and tempering, we alter the microstructure of the steel to achieve the desired balance of hardness, strength, and ductility. Our heat treatment facilities include oxygen-free bell-type annealing furnaces, lead bath quenching lines, oil quenching lines, and water quenching lines. These processes allow us to tailor the properties of the steel to meet specific application requirements, ensuring that our products can withstand high stresses and demanding conditions. By rigorously controlling the heat treatment parameters, we produce steel strips with superior mechanical properties that provide exceptional durability and reliability.

Surface Quality

Surface quality is a critical aspect of our production process, and we employ advanced grinding and polishing techniques to achieve a flawless finish. Our grinding operations remove surface imperfections and ensure a smooth, uniform texture, while our polishing processes enhance the steel’s aesthetic appeal and functional performance. We utilize state-of-the-art machinery and precision tools to achieve the desired surface roughness, ensuring that our steel strips meet the highest standards of quality. The polished surface not only improves the visual appearance but also enhances the steel’s resistance to corrosion and wear. By focusing on surface quality, we provide products that are not only visually appealing but also perform reliably in their intended applications.